-

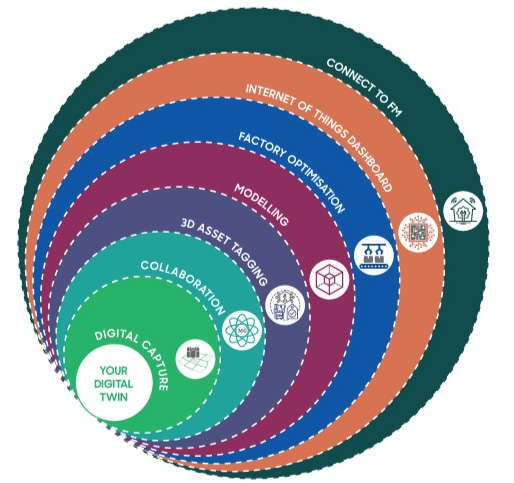

Digital Twin – Your Choice, Your Priorities

In manufacturing, flexibility is crucial, and having a central hosting system is essential. Manufacturers often strive to achieve secure access to a single version of accurate and reliable information, which is the common goal.

Cadline’s Digital Manufacturing team possess the necessary skills and industry expertise to assist in defining a digital strategy, helping to deliver the specific components that are important within a unified hosted environment.

We will help you host your digital content, add data and value over time, integrate with downstream facilities systems or simply scan, model and provide virtual walk throughs of your shop floor.

Download Smart Factory Brochure Enquire now about building your Manufacturing Digital Twin -

Smart Factory

Build and Host your Manufacturing Digital Twin

Get in touch

Digital Capture

-

Digital Capture

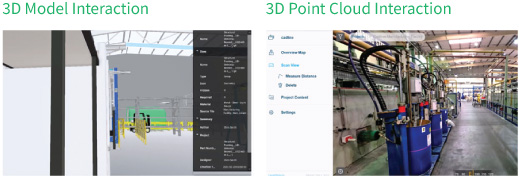

Factory, Equipment, Building, Plant and Site – capture assets within 1mm accuracy and deliver a usable model of the equipment, internal and external environment and plant providing the accurate data needed as a foundation for a digital twin.

Download Smart Factory Brochure -

Collaboration

-

-

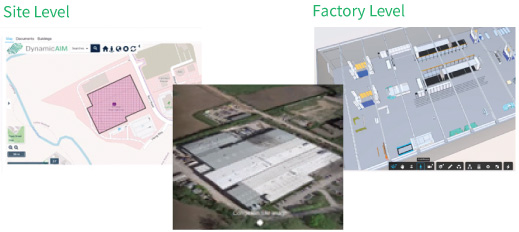

Collaboration

Create a secure immersive 3D virtual user experience with walkthroughs for multiple stakeholders using rapid 3D Photo scanning of factory, production facilities, buildings, core, boiler rooms, IT Hubs, corridors, interiors, corridors, ceilings, floors, balconies and assets to capture digital data and real-world special representations.

Download Smart Factory Brochure

3D Asset Tagging

-

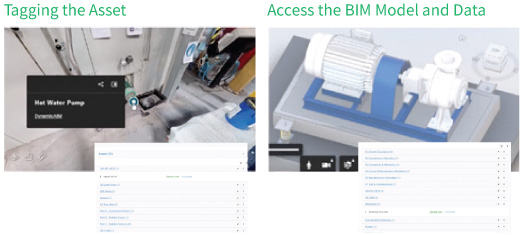

3D Asset Tagging

Tag 3D equipment and data with digital asset information such as O&M manuals, equipment training manuals, assembly and disassembly videos, maintenance schedules or any BIM models and asset documentation that needs to be securely accessed by wider teams.

Download Smart Factory Brochure -

Modelling

-

-

Modelling

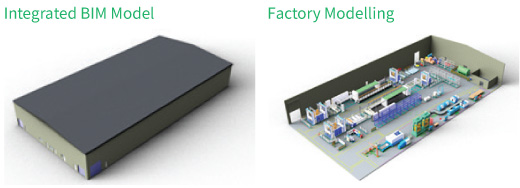

Define the models and collaboration experience based on purpose and usage. For example, create a digital asset strategy; scan existing building and equipment assets, model and tag for use by maintenance and facilities.

Optimise the environment ahead of construction work taking place, incorporate BIM construction models early in the design phase to allow space to be digitally planned and factory and production layouts to be reviewed and simulated.

Download Smart Factory Brochure

Factory Optimisation

-

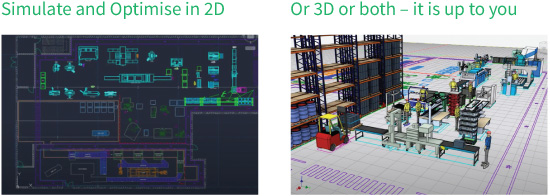

Factory Optimisation

Digitally capturing factory assets is just the start. Once captured, add manufacturing through put data to model, simulate and optimise factory layouts, proving what if scenarios without moving any equipment or people until optimal solutions have been found. Simulate energy consumption comparisons to help reduce costs and environmental impact.

Download Smart Factory Brochure -

Internet of Things Dashboard

-

-

Internet of Things Dashboard

Capturing sensor dashboard information for proactive maintenance of equipment can be hosted and accessed in the same environment as any other digital twin assets. Linking real world IOT data back to a central environment delivers the best real-time experience for teams and perhaps provides opportunities for new product offerings and go to market experiences for customers.

Download Smart Factory Brochure

Connect to FM

-

Connect to FM

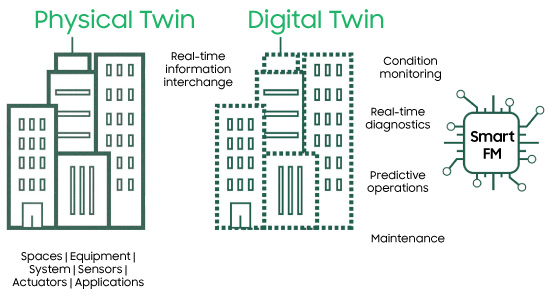

Better manage asset lifecycles through Design, Build, Operate and Maintain phases when you integrate digital twin data and facilities management systems and connect teams to up to date information.

Download Smart Factory Brochure -

Speak To Us Today

GET IN TOUCH

Your cart is empty

What would you like to buy? software products, training courses, or support packages

Total:

£0.00